The History of the Bagley & Sewall Co.

… as written in the Bagley & Sewall Company pamphlet c.1946

B&S History c.1946

In the Spring of 1823, there arrived in the little village of Watertown, George Goulding, a young machinist and millwright who was destined to found what has become one of the oldest and largest manufacturing establishments in Watertown and Northern New York. His first machine shop was located in a building that was on a site that is part of the present Farwell and Rhines Flouring Mills property on Fairbanks Street. In 1944 the company purchased the site on which is located the Farwell and Rhines Company. This property was being offered for sale by the RFC and was purchased only for the historical value connected with Bagley & Sewall.

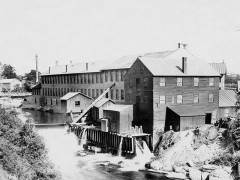

George Goulding continued his business until April 10, 1840, when he bought real estate and water rights and built a new shop on Sewall?s Island on the north branch of Black River. He was a mechanical genius, and he was called upon to build and install all kinds of machinery for the many industries that were rapidly springing up in this country. At the beginning of the year 1853, his business had increased to the point where more capital and more executive ability were needed. So, the partnership of Goulding, Bagley and Sewall was formed September 12, 1853, and the value of the business and plant at that time was $19,000.00. George A. Bagley and Edmund Q. Sewall were both lawyers by profession, but the practice of law was distasteful to both of them so they gave it up to engage in business.

The new co-partnership prospered and their business expanded rapidly until they not only furnished machinery for Northern New York, but they equipped many of the early flouring mills of Chicago, Milwaukee and Minneapolis. They also built machine tools which were designed by Mr. Goulding. The co-partnership of Goulding, Bagley and Sewall was dissolved August 27, 1860, and the same day the partnership of Bagley and Sewall was formed. George Goulding continued as superintendent with Bagley and Sewall until 1865. He died June 24, 1878.The Bagley & Sewall Company was incorporated July 7, 1882. Mr. George A. Bagley was elected president and Mr. Edmund Q. Sewall secretary and treasurer.

In 1870 Senator Warner Miller and Mr. Churchill of Herkimer, New York, purchased in Germany the patents for the principle of making groundwood pulp, and Bagley and Sewall built the first Voelter grinder made in the United States. They also built the first spring wet machine to handle the pulp made from these grinders.

As Watertown is located in what was then the heart of the paper-making industry in Northern New York, it was concluded at that time that this was the logical location for a plant to build paper-making machinery. In 1889, new buildings were erected and new machinery installed, and the building of high-grade Fourdrinier and Cylinder paper-making machines was begun and has since been the principle product of this company. Paper-making machines have been supplied by the Bagley & Sewall Company to the leading mills of the United States, Canada, Newfoundland, Great Britain, France, Norway, Sweden, China, Japan, Brazil, Mexico and Russia. Bagley & Sewall were the first machinery manufacturers to produce a machine capable of producing paper continuously at 1000 lineal feet per minute.

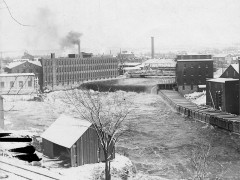

In 1912, the company had outgrown itself and it became necessary to build new shops. As the result, Bagley and Sewall was equipped to build the wider and faster machines that were then being demanded by the paper trade.Bagley & Sewall selfishly claim to have one of the largest and best equipped machine shops and foundry in the country capable of producing paper-making machinery. The most modern facilities make it possible for them to construct paper machines up to 325? in width, and the largest machine ever built and operated in the Western Hemisphere is a Fourdrinier Machine having a wire of 304? built by the company. This machine is now running at the Great Lakes Pulp and Paper Company, Fort William, Ontario.

Bagley & Sewall is justly proud in having been a leader in the March of Progress in the development of the paper industry to its present peak. This record has been accomplished only by the cooperation and constructive suggestions of the faithful employees of the company.

At the beginning of World War II, the company took several contracts for both the Army Ordnance and the Navy Department. One of the first large contracts signed was for fifty (50) large Betts Boring Mills which were urgently needed at the beginning of the war for the turning of tank turretts. It became apparent that our core-making facilities were inadequate for the size and number of cores required for the large boring mill. In May 1942, ground was broken for a new core room. This building is 80 ft. wide by 220 ft. long. Three large core ovens at the east end of the building give a core-baking capacity ample for all our requirements. A battery of four small ovens called ?day ovens? are also located in this core room.In 1944, the company took a contract with the Army Ordnance for over a million 105 mm shells. Ground was broken for a new building on Moulton Street, March 20, 1944, which was to be used for the construction of these shells. In October of the same year, the company was in production on these shells. When the war ended in August 1945, 716,525 shells had been produced in this building. During the war period, the plant personnel increased to over 1200 employees.

Both the core room and this building adapt themselves for the manufacturing of paper-making machinery, and both are being used to full capacity in the construction of paper machinery. At present, there are 650 employees working in the Bagley & Sewall shops.

The name of Bagley & Sewall is not only known in the United States but is world renown, and this has been brought about only by the long and faithful service given by its employees.